Our History

Follow the timeline down to learn more about the history of EBway and GRIPflow®.

The Beginning

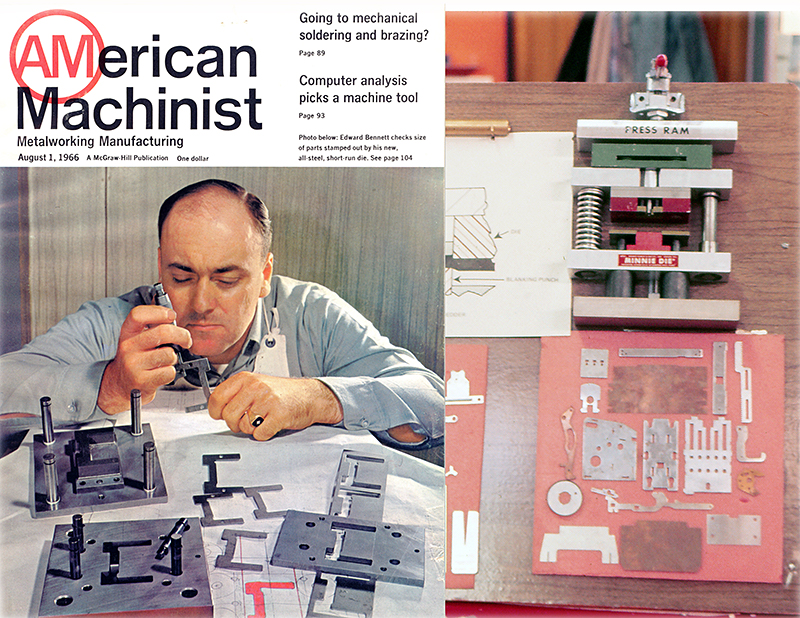

The company originated in 1961 under the name of Minnie Punch & Die Co. in Union, New Jersey. It’s founder, Edward Bennett, had invented the Minnie Die which was a low cost stamping tool for materials up to 0.125” thick. This unique technology was patented and licensed to many tool and die companies throughout the United States and in 35 countries of Europe and Asia.

“Grip” Technique is Born

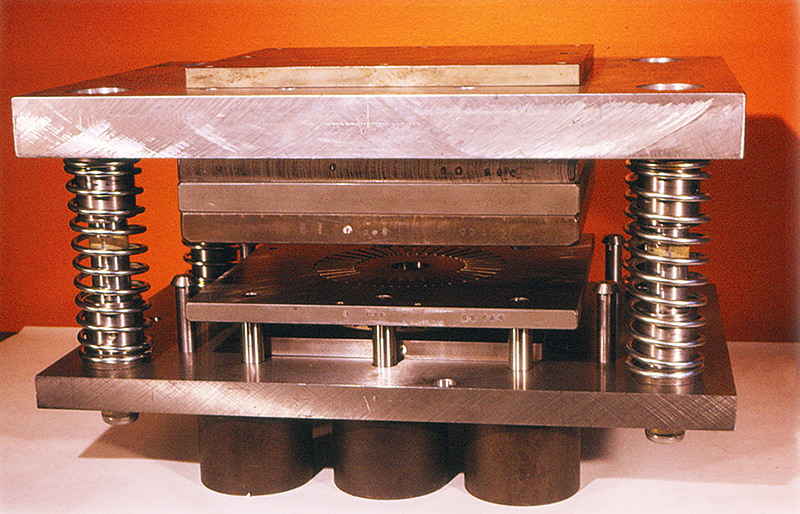

Mr. Bennett developed a new tooling system for conventional stampings called “Grip Blanking”. Grip Blanking dies were more durable than the Minnie Dies and had the advantage of stamping thicker metals with longer production runs. It was with the development of this technology that triggered the changing of the name of the company to EBway Corporation.

Hello, South Florida!

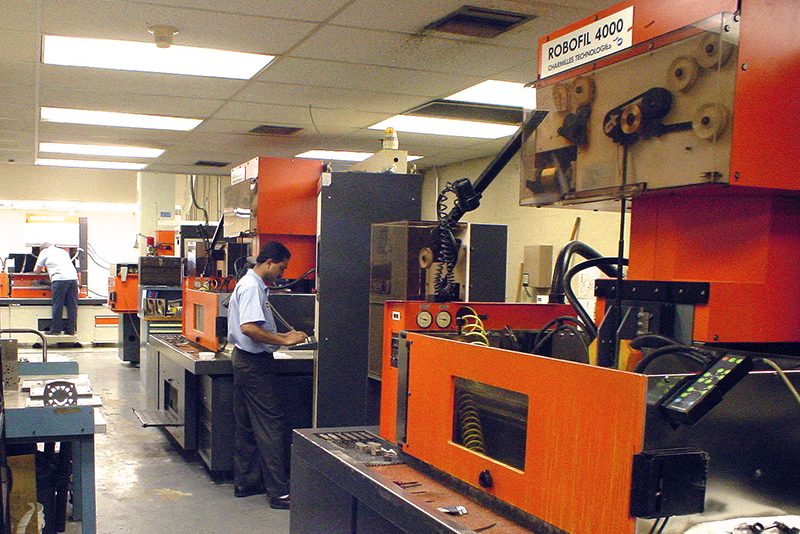

EBway Coproration moved from New Jersey to its new facility in Ft. Lauderdale, Florida. Soon afterward, EBway purchased its first pair of Wire Electrical Discharge Machines (Wire-EDM). These new, accurate machines were used to cut the punch and die details. The Wire-EDM machines were also made available to other mold and die shops in South Florida. EBway was the first in Florida to offer a Wire-EDM subcontract service.

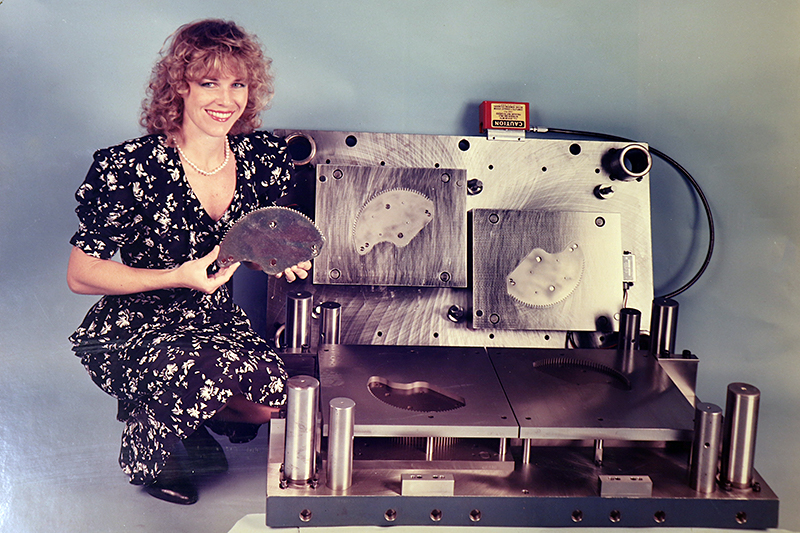

The Best Fineblanking Atlernative

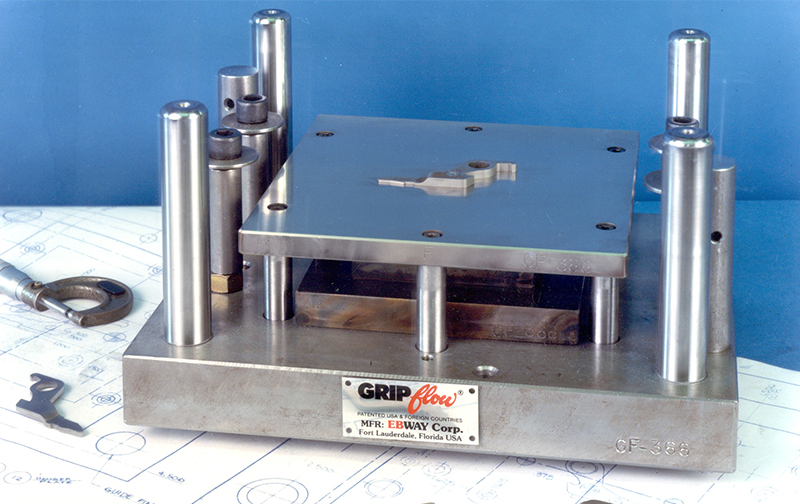

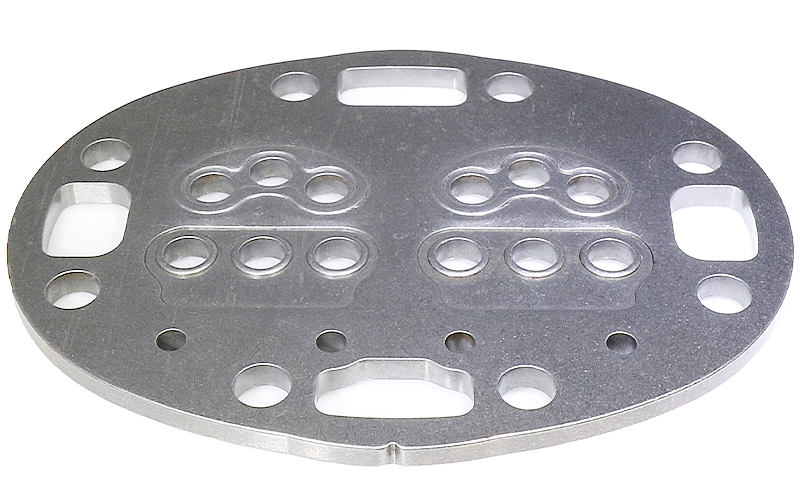

Wire-EDM was the missing link in the finalization of an idea that Ed Bennett had been tooling with for years. He was able to develop a way to make smooth edge stampings that exceeded the quality and accuracy of conventional stampings. This new technology was called “GRIPflow®” and became an economical alternative to fineblanking.

Advancements Continue

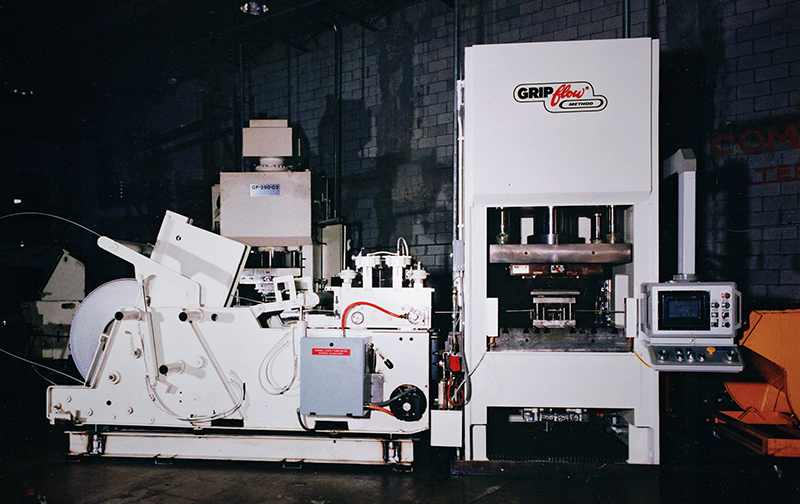

EBway introduced GRIPflow® through trade shows and articles in various news publications. EBway expanded its building to accommodate the new addition of GRIPflow® production presses. GRIPflow® technology continued to improve producing thicker parts, smaller holes, complicated coined features and added more features to its single station compound dies and progressive dies.

Better Prog Dies

EBway developed its GRIPflow® progressive dies to do more detailed forming and coining. This technological breakthrough enabled EBway to produce parts with coins and chamfers on both sides, coined counterbores, and extreme jogs in parts. These progressive dies required more accurate feed lines which EBway accomplished by working with German feedline manufacturers.

Movin' On

Ed Bennett retired and the next generation took over the management of EBway. EBway Corporation became an LLC. With the help of lean manufacturing and continued growth, EBway was able to merge both the tooling and production facilities under one roof. EBway became a woman-owned business and received its ISO 9001:2015 Certification.

The Future Of EBway

EBway currently owns its buildings and equipment and is debt free. EBway’s Research & Development Team is continuously exploring ways to improve the quality, reduce the cost of its manufacturing operations and develop new technology. The third generation is now working at EBway to eventually make a smooth transition into management.

Download the  Design Guide

Design Guide

Contact Us

Fill out our form to get in touch.