Some remarkable features of GRIPflow® are the following:

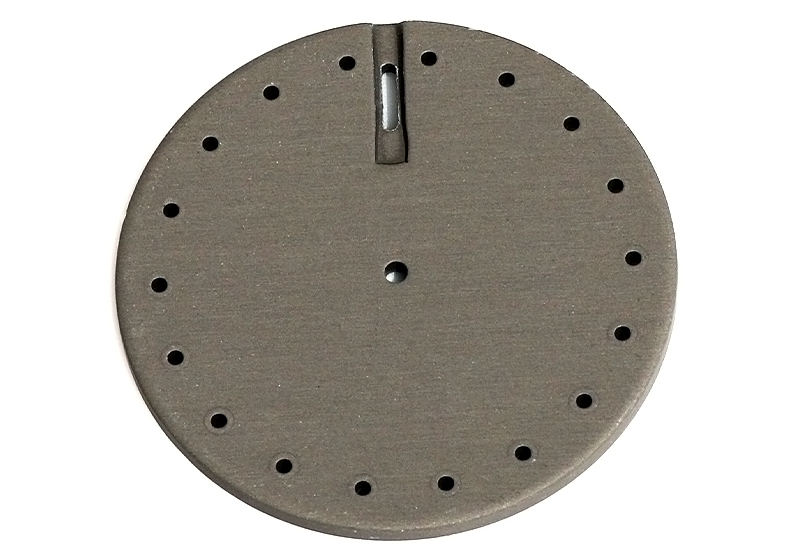

True square edges with a full bearing surface. The edges are parallel to each other and perpendicular to the top and bottom surfaces.

Excellent part to part repeatability.

Tolerances as low as 0.0005” and part flatness to 0.001” per linear inch.

Edge finishes of 32 RMS are typical.

Producing holes smaller in diameter than the material thickness is normal. Holes as small as 30% of the material thickness have been achieved.

Round or shaped holes can be extremely close to each other or to the part edge – a web as small as 30% of the material thickness has been achieved.